SWIFT FLOATING SURFACE COLLECTOR DOWNSTREAM FISH PASSAGE

LEWIS RIVER, WA

As a sub-consultant to Black & Veatch, Art Anderson (AA) provided multidisciplinary engineering design services for a $60 million-dollar Floating Surface Collector (FSC) Barge and Access Trestle that serves as a downstream Fish Passage Facility for PacifiCorp’s Swift No. 1 Hydroelectric Project on the Lewis River in rural southwest Washington State. The Fish Passage Facility was developed as a result of PacifiCorp’s settlement agreement for the relicensing of its hydroelectric facilities. In accordance with the Lewis River Hydroelectric Projects Settlement Agreement (SA), “restoration of anadromous fish runs will be established around the Merwin, Yale, and Swift Dams, and fish will spawn and rear naturally in the habitat available upstream of Swift Dam. Juvenile fish migrating downstream from this habitat will be collected with new fish passage facilities at Swift Dam.”

AA’s scope of work for the contract with Black & Veatch was broken into two phases, Phase 1 resulted in the concept design for the project and Phase 2 developed the PS&E Package for the final design and construction bid package. The scope of work for our firm included engineering analysis, design, and construction support services for the Fish Passage Facility, including the design of the FSC barge; instrumentation and controls; the access trestle; agement systems; and the fish sorting and handling systems.

A large fluctuation in the reservoir was one of the primary engineering challenges Art Anderson faced in the design of the barge’s mooring and access. Our solution included a braced pile trestle; a 10-story mooring tower designed to handle heavy service loads; a work platform to allow maintenance of barge mechanical systems via mobile cranes; a 20-ton bridge crane system; and personnel access systems to and from the barge.

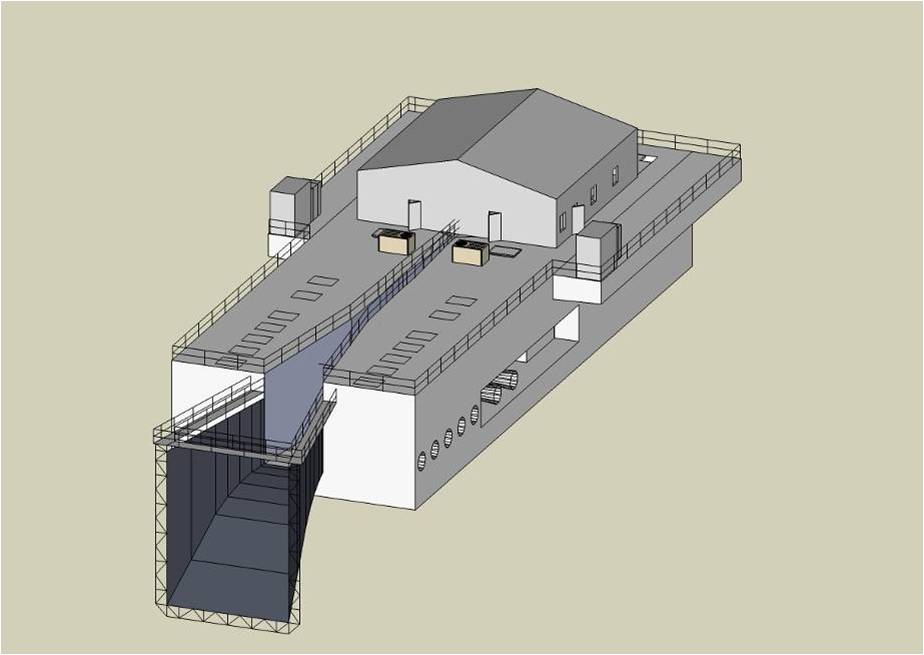

The FSC Barge is a floating platform with dimensions of 82’x170’x28’ and includes a variety of complex mechanisms for collecting, sorting, sampling, and tagging downstream-travelling juvenile salmon. These complex mechanisms include screens, channels, baffles, cleaners, flumes, holding tanks and pump systems.

Art Anderson provided all naval architectural and marine engineering analysis and design services for the FSC barge and ballast system, taking into account worker safety, ease of maintenance, life-cycle costs, and system redundancy requirements. The FSC Barge is intended to operate continuously, during all flows and seasons, for a 50-year life cycle. Therefore, designing to minimize downtime, or allow “hot-swapping” equipment that will wear out or break during ongoing operations was an important design criterion.

The FSC is moored to a fixed structure consisting of two primary elements: a 650’-long multi-span trestle erected with 18’-wide by 110’-long pre-fabricated bridge trusses, and the 185’-tall FSC mooring tower that doubles as a hopper-to-truck fish transfer work platform.

The site is remote, with restrictive access. An overall design and procurement strategy for this project was to design to accommodate, to the maximum extent possible, off-site prefabrication through modularization, thereby minimizing expensive on-site assembly. Trucking contractors were engaged to determine the largest prefabricated items that could be safely transported to the site. To facilitate field assembly and provide for future maintenance of the FSC, a dry dock facility was constructed on the Swift Reservoir. The facility included an earth-filled channel and sheet pile cofferdam system and included a mooring system to facilitate movement of the FSC in and out of the facility. It also included a dewatering system to remove accumulated water within the drydock. Our firm was responsible for developing the dry dock requirements, permits, design and bid documents to a sufficient level for a competitive design/build procurement.

PROJECT DATA

DELIVERED ON TIME

DELIVERED ON BUDGET