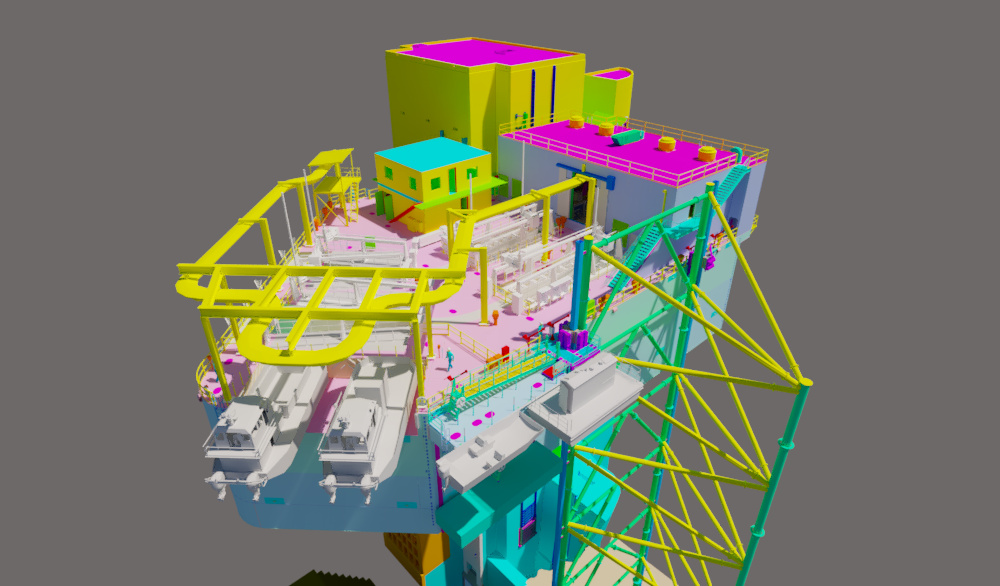

COUGAR FLOATING SCREEN STRUCTURE

COUGAR RESERVOIR, OR

The U.S. Army Corps of Engineers (USACE) identified a need for a small-scale, portable floating fish collection (PFFC) device to gather additional information on juvenile fish movement in Willamette Valley Project (WVP) reservoirs. This device was intended to provide a cost-effective means of safely obtaining juvenile fish in WVP reservoirs for use in research, monitoring and evaluation efforts as well as to gather information on the behavior of both tagged and run of river fish near and within a small floating surface collector. There are three planned deployments for the device: Lookout Point, Detroit and Cougar Reservoirs. Of these Cougar Reservoir represented the most challenging of the installations due to the large storage capacity provided for flood control and resulting wide range of reservoir water surface elevations. The PFFC design ultimately provides the USACE a device that can be broken down into components sized to allow safe and normal transport over the state highway system.

Art Anderson provided Naval Architecture and Marine Engineering for the design of the PFFC. A compressed design schedule was met by designing the floating fish collector in-house as an integrated vessel with multiple sub-systems. Art Anderson completed the design of all structural elements with the exception of the fish collection module designed by HDR.

Working from concepts developed for the feasible solution to the portable floating fish collector (PFFC) requirements, the following tasks carried the design to be released for construction and installation bids.

Task 1: Vessel Design

Art Anderson provided the HDR Team with marine structural specifications, structural sketches for drafting in Microstation 3D and sealed design drawings and specifications for marine structures for the design of the PFFC Vessel. Design elements included: A flow containment shell with support beams and associated foundations for the fish collection module to be suspended in the bay between floatation devices required to support the loads. Foundations to support fish collection flow pumps (designed by others) inside the flow containment shell. A gantry rail crane system including features to support operational requirements in fish collection and mooring. Elevated deck grating and structural grating supports that included removable deck sections for operational access to the fish collection components; hatches; modular assembly and disassembly; clearance and support for electrical, hydraulic and mooring wire runs. Vessel outfit foundations for winches, fairleads, switch gear, VFDs, cable spooler, lighting and other deck mounted equipment. Handrails and personnel access points.

Art Anderson also delivered the vessel’s Weight Estimate and calculated weights, drafts, and trim for the full operational load case with pumps running and mooring loads applied; hydrostatic calculations to confirm stability over the range of anticipated operating conditions; calculations for the connector loads for the flexi-floats and specifications for connectors; performed an auditable QA/QC Review; and maintained coordination with other members of design team.

Task 2: Mooring System Design

The existing conceptual mooring system was reviewed and the design advanced using maximum current and wind event values provided by the Corps. Mooring calculations were used to determine the fleeting mobility of the moored barge within operational watch circles at multiple pool elevations. Calculated mooring loads provided the basis for winch, wire and anchor selection and set the levels for load rendering in the mooring winches.

Art Anderson provided Naval Architecture and Marine Engineering for design basis calculations of the environmental loading on the floating fish collector (wind, current, and waves) based on environmental criteria provided by the Corps; definition of the watch circle and loads on the mooring system over the range of anticipated reservoir elevations (185 feet of variation) and environmental loads; calculations to define the size and type of anchor specified for the system; and completed calculations of the anticipated rendering loads to support the development of wire rope, winch, and hydraulic power unit specifications. We developed the construction specifications for the fairlead, anchors, wire rope, connectors, winches, and hydraulic power unit. Also provided mooring system sketches for drafting in Microstation 3D.

Task 3: Marine Operations Plan

Art Anderson developed a marine operations plan and the associated costs to enable the deployment and recovery of the PFFC and associated devices at Cougar Reservoir. These plans demonstrate the method for deployment and recovery of modular vessel sections from trucks; provide instructions for the assembly and disassembly of the floatation devices and all other modular components; show deployment and retrieval plans for the anchors and mooring system; and show deployment and retrieval plans for the subsea power cable.

PROJECT KEY HIGHLIGHTS

Integrated Floating Structure to support Client Designed Fish Sys.

Developed Bid Level Drawings & Specifications

Prepared Construction Cost Estimates

Floating Structure Designed to ABS Standards

Electrical Distrubution

Intact & Damage Stability Analysis

Manned & Unmanned Space Ventilation System

Automated Ballasting & Trimming System

Mooring Connection Structural Design

PROJECT DATA

DELIVERED ON TIME

DELIVERED ON BUDGET