CANTILEVER SLABS FORMING

SILVERDALE, WA

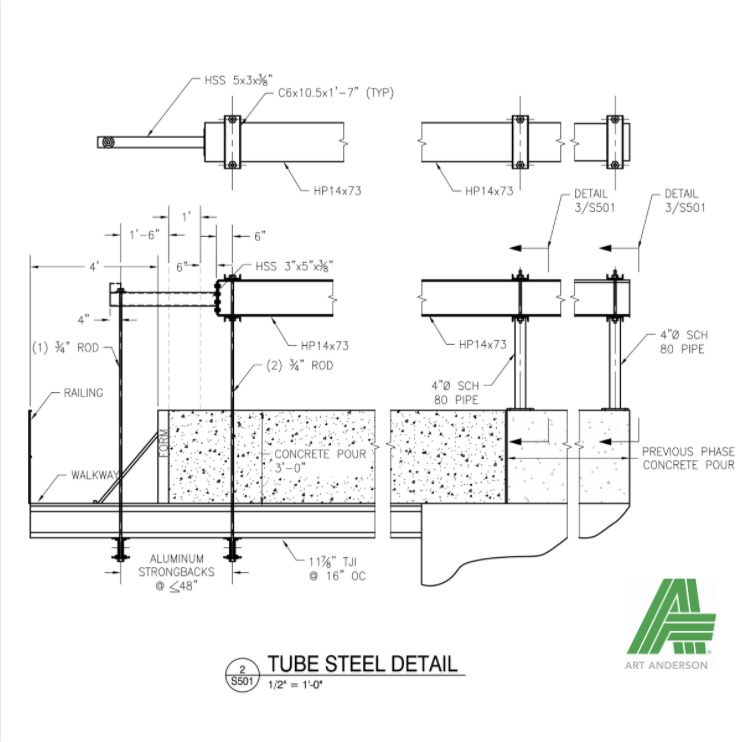

The Navy designed a new waterfront support building that included concrete walls and a new slab. The new building would sit on sheet piles and part of the building was designed to overhang the sheet piles. To be able to pour the slab, design drawings for the formworks for the cantilevered slab were required. Adequate support while the concrete cured was critical to the success of the project and attaching to the sheet piles was not an option. Our in-house team designed a system of steel beams, aluminum strong backs and plywood to create platforms that were supported by previously cured concrete. We developed a sequence and divided the areas into sections to be poured. The final slab would be three feet in thickness.

Deflection was a major concern for this project. As the slab was the foundation to a building, it had to be level. The beams and formworks had to account for deflection from the weight of the concrete. Our team chose steel beams that were larger than necessary and tried to predict the deflection in order to offset it.

All of the formworks were only needed temporally during construction. We designed the bracing system in such a way that the beam could be reused on other projects. We didn’t drill unnecessary holes or do anything else that would compromise the integrity of the beams.

PROJECT DATA

DELIVERED ON TIME

DELIVERED ON BUDGET